ABOUT PROJECT

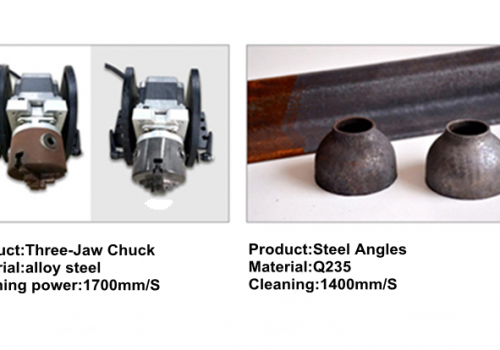

Laser cleaning, in terms of its mechanism for mold cleaning, uses a clean substrate (also called a precursor) and a surface attachment (soil) to have a very different absorption coefficient for a certain wavelength of laser energy. Most of the laser energy radiated to the surface is absorbed by the surface deposits, which is heated or vaporised and evaporated, or instantaneously expanded, and is driven by the vapour stream formed on the surface to separate from the surface of the object for cleaning purposes. Specifically used for tyre mold cleaning, the mold absorbs laser light of a specific wavelength, the energy is very small, and will not cause damage. The dirt on the surface of the mold (sulphide, inorganic oxide, silicone oil, carbon black, etc.) absorbs a large amount of energy and is instantly expanded. Vaporisation evaporation, away from the mold surface, to achieve the effect of cleaning. The main methods of laser cleaning are:

1) Laser dry cleaning method, that is, direct radiation de-contamination using pulsed laser;

2) Laser + liquid film method, that is, first deposit a liquid film on the surface of the substrate, and then decontaminate with laser radiation;

3) Laser + inert gas method, that is, while the laser radiation is being used, the surface of the substrate is purged with an inert gas.

When the dirt is peeled off from the surface, it will be immediately blown off the surface by the gas to avoid re-contamination and oxidation of the surface;

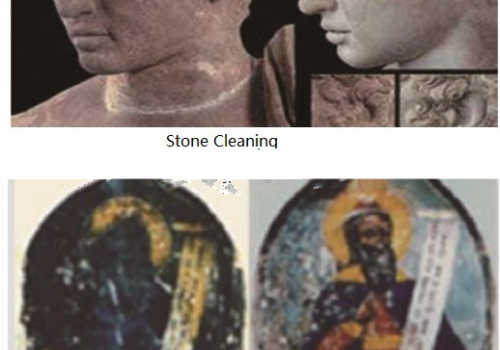

4) Use a Laser to loosen the dirt and then clean it with a non-corrosive chemical method. Currently, the first three methods are commonly used. The fourth method is only found in the cleaning of stone artefacts. The advantages of laser cleaning are high efficiency, speed, low cost, low heat load and mechanical load on the mold, and will not damage the workpiece to be cleaned; waste can be recycled without environmental pollution; safe and reliable, without damaging the health of the operator; It can remove dirt of various thicknesses and different

compositions; the cleaning process is easy to achieve automatic control, remote remote cleaning and so on.