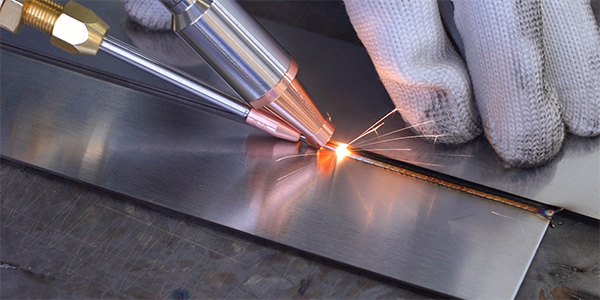

Laser Welding Stainless Steel

ステンレス鋼のレーザー溶接の用途

Laser welding is a high-precision, high-quality and efficient method suitable for various thicknesses of stainless steel materials, and it can weld complex shapes and geometric structures, offering exquisite and smooth welded seams, making it suitable for a wide range of industries.

Laser welding is commonly used for joining stainless steel components, such as pipes, containers, brackets, and steel structures. Stainless steel parts: door and window frames, cabinets, kitchenware, sinks, automotive parts, and more.

The stainless steel 300 series (含む 304, 316, 321, NS。) is suitable for laser welding and can be used in the manufacturing of food processing equipment, medical devices, railings, door and window frames etc.

The stainless steel 400 series (含む 410, 420, 430, NS。) typically contains higher hardness and can be used in the production of cutlery, 調理器具, 食器, and some mechanical components.

Duplex SS: such as 2205 (UNS S31803), possesses excellent strength and corrosion resistance. Laser welding is suitable for manufacturing marine engineering components, chemical industry equipment, marine equipment, and more.

Stainless steel alloys: Some stainless steel alloys to meet specific application requirements.

Why Choose Laser for Stainless Steel Welding

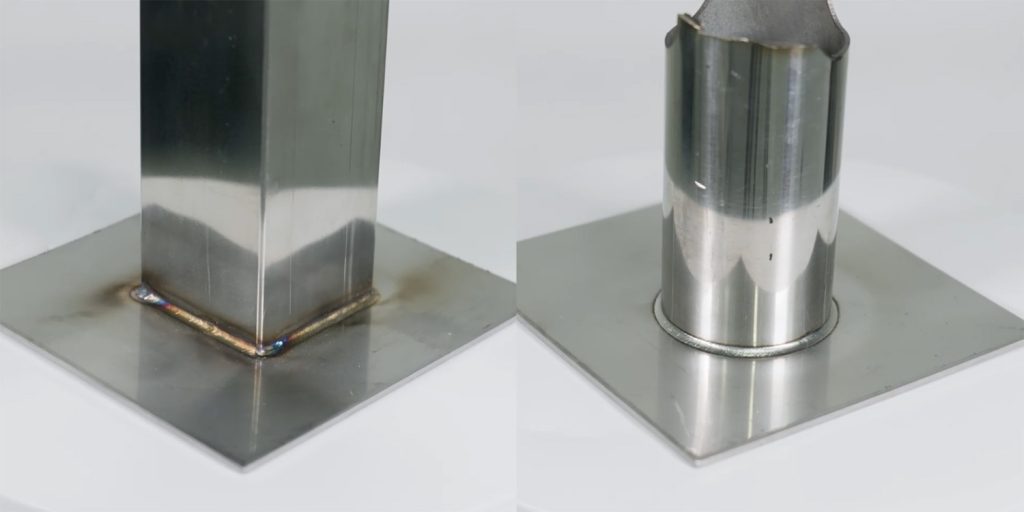

| Argon Arc Welding VS. Laser Welding | ||

| Items | Argon Arc Welding | Laser Welding |

| Heat | High heat | Low heat |

| Deformation | Prone to deformation | Minimal or no deformation |

| Weld Bead | Large weld bead | Smaller weld bead, adjustable spots |

| Aesthetics | Requires processing, high grinding costs | No need for post processing and low processing costs |

| Penetration | Susceptible to perforation | Not prone to perforation |

| Shielding Gas | Requires Argon gas | Requires Argon/Nitrogen gas |

| Precision | traditional | High precision, Computer numerical control (CNC) |

| Efficiency | traditional | 2-5 times faster |

| Safety | Intense ultraviolet radiation | Safe irradiation, almost no harm |

| Skill Requirements | Skilled welders | No technical requirements |

Stainless Steel Laser Welding Samples