À PROPOS DU PROJET

Railways mainly use seamless rails with a coverage rate of 70%. Dans la production ferroviaire sans soudure, the key sequence is rail welding, et la technologie de nettoyage du rail est très importante pour le soudage.

Traditional polishing faces many problems

1. Deep grinding to ensure cleanliness, but it destroys the curved surface appearance of the rail surface and affects the passenger’s ride comfort.

2. Reduce the amount of sanding to ensure the appearance of the arc surface, but lead to serious rust residue, and produce a huge safety hazard.

3. Consuming a large amount of grinding wheel consumables, which is expensive, has serious environmental pollution, and has serious harm to workers’ health.

4. The work efficiency is low, the cleaning cycle is long, and the labor cost is increased invisibly. Modern laser cleaning brings new efficient technology.

5. The cleaning light source can adapt to the curved surface shape of the rail to minimise the damage of the substrate.

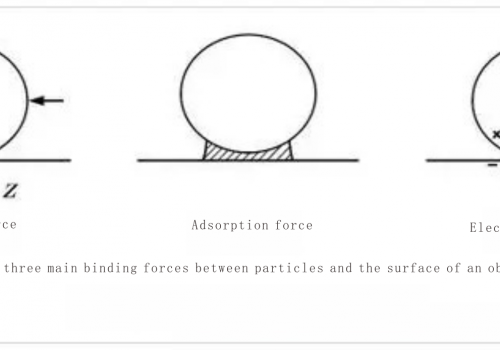

6. Laser cleaning can achieve selective removal of contaminants, improve cleanliness and protect substrates.

7. Green cleaning technology means no consumables, eliminating dust pollution and greatly reducing cleaning costs.

8. The cleaning light source can utilise the flexible transmission of optical fiber to cooperate with the robot integration work to improve work efficiency in the workshop.

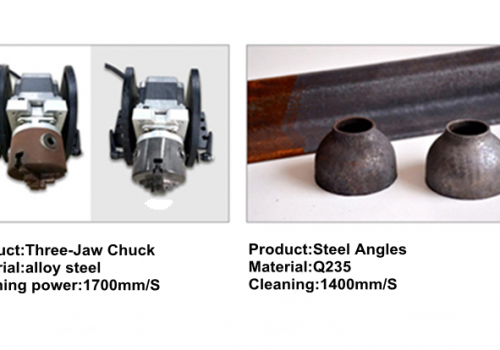

Steel maintenance and repair tasks are arduous. As a high-tech cleaning technology in the new generation by Keslon Laser Cleaning is crucial to solve the problems of high scrap rate, high cost, and high environmental pollution, but also related industries. Scientific research and technological progress now bring huge economic and social benefits!