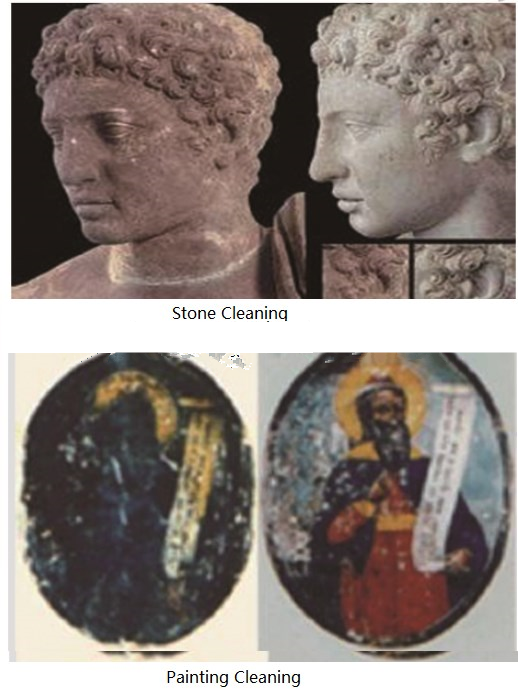

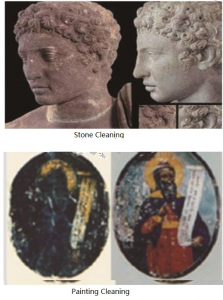

Laser cleaning technology gently removes and cleans marking and deep engraving dirt on sandstone, marble, granite, clay and concrete without physical damage or damage to the building’s surface. The laser can finely clean the surface of the coloured or pigmented surface to remove accumulated smoke and unsightly dirt and restore the original beauty. Extremely precise adjustments are made by the laser power (0-100%) and intensity in the system.

Related Projects

MOLD LASER CLEANING

ABOUT PROJECT Laser cleaning, in terms of its mechanism for mold cleaning, uses a clean substrate (also called a precursor)…

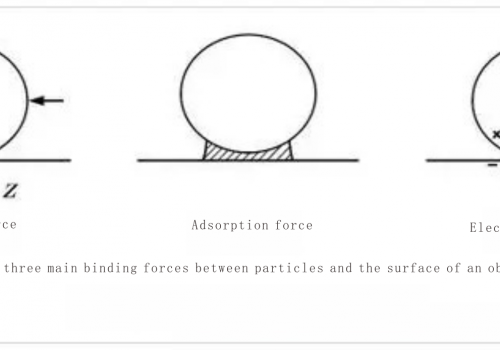

The principle and application of laser cleaning

Laser cleaning has the cleaning characteristics of non-grinding, non-contact, low thermal effect and suitable for objects of various materials, and…

PRE-TREATMENT PARTS BEFORE PRIMER PAINTING

ABOUT PROJECT The Keslon laser cleaner machines have the technology needed to prepare the surface prior to coating, removing almost…

WELDING PRE TREATMENT NDT

ABOUT PROJECT Laser cleaning uses NDT non contact methods to remove metal, black and non-ferrous lubricants, providing high quality, smooth…